Concrete floors take more abuse than almost any other surface in a home or commercial space. Vehicles, moisture, chemicals, and daily wear all leave their mark over time. That’s why property owners increasingly turn to epoxy floor coating services when they want long-term protection paired with a clean, finished look. Epoxy doesn’t just improve appearance. It strengthens the surface, seals the concrete, and creates a floor that performs reliably year after year.

What Epoxy Floor Coating Really Does for Your Concrete

Epoxy floor coating forms a bonded layer over concrete rather than sitting loosely on top. Once applied correctly, the coating hardens into a seamless surface that resists moisture, stains, and abrasion. This bond helps protect concrete from cracking, dusting, and chemical damage.

Unlike paint or basic sealers, epoxy penetrates prepared concrete and cures through a chemical reaction. That process creates strength, not just coverage. As a result, floors handle vehicle traffic, dropped tools, and frequent cleaning without breaking down. Because epoxy seals pores in the concrete, it also prevents oil and liquids from soaking in, which keeps the surface cleaner and easier to maintain.

Where Epoxy Floor Coating Services Make the Most Sense

Epoxy performs well in spaces that demand durability and cleanliness. Garages remain the most common application, especially for homeowners who want a floor that resists tire marks and oil stains. Workshops benefit as well, since epoxy creates a smooth surface that sweeps easily and holds up under heavy equipment.

Basements also see strong results from epoxy coatings. Sealing the concrete reduces moisture intrusion and dust, which helps turn unfinished basements into usable living or storage spaces. In commercial environments, epoxy coatings support foot traffic, equipment, and sanitation requirements without constant upkeep.

Because epoxy adapts to many environments, professional epoxy floor coating services tailor each system to the space. Thickness, texture, and topcoat selection all change based on how the floor will be used.

Why Professional Application Matters

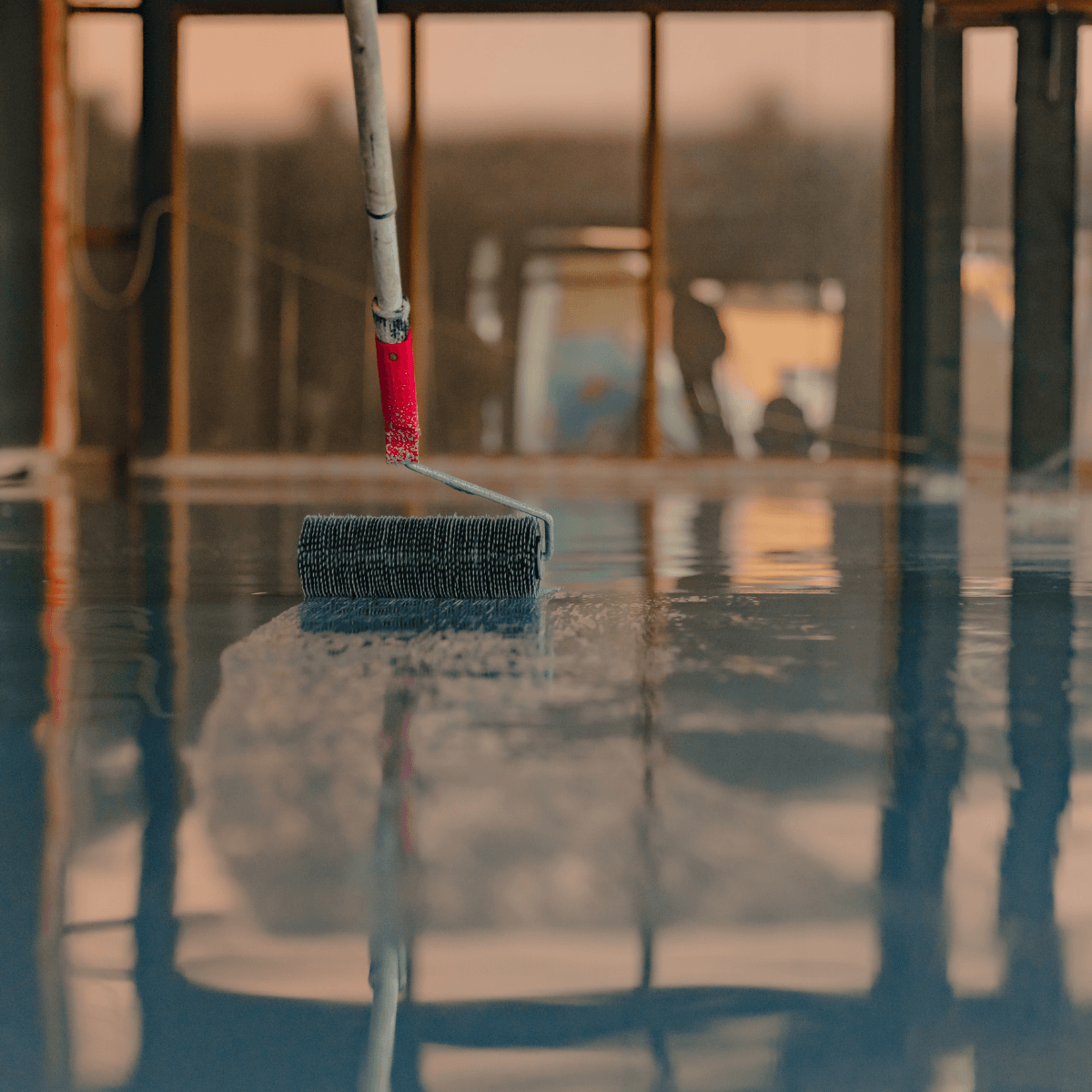

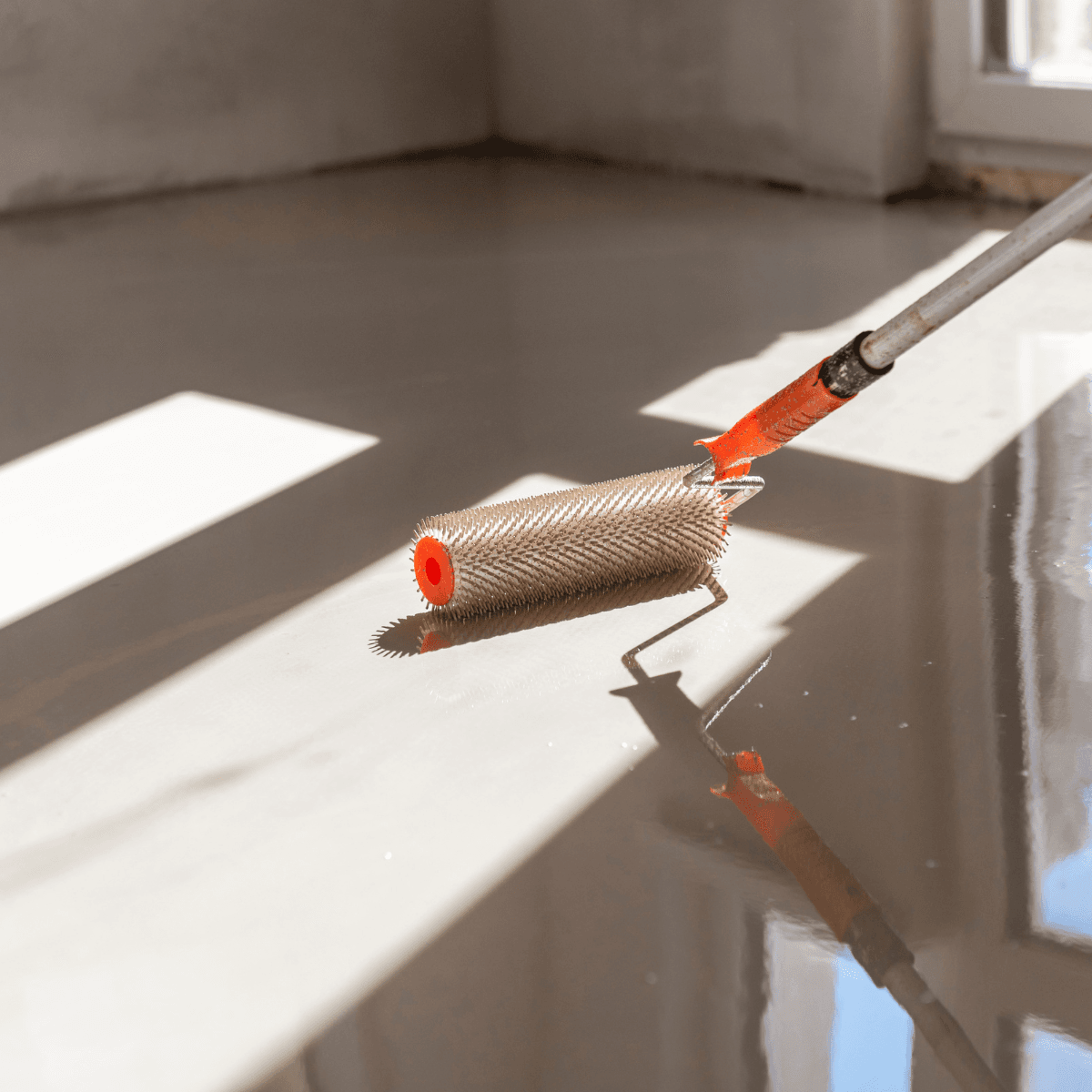

Successful epoxy flooring depends on preparation more than anything else. Concrete must be clean, properly profiled, and free of moisture issues before epoxy goes down. Without professional surface grinding or shot blasting, the coating may peel, bubble, or fail prematurely.

Experienced epoxy floor coating services begin by evaluating the concrete itself. Moisture testing, crack assessment, and surface hardness checks guide the installation approach. Grinding equipment opens the concrete pores so the epoxy bonds correctly. Environmental conditions also matter. Temperature and humidity affect cure time, so professionals monitor those variables closely throughout the process.

Layer timing plays a role as well. Epoxy systems often include base coats, decorative layers, and protective topcoats. Each layer must be applied within specific windows to ensure proper adhesion. Professional installers manage that timing carefully to deliver a smooth, uniform finish.

Design Options That Balance Style and Performance

Modern epoxy floor coatings offer far more than a plain gray surface. Color flakes, quartz blends, and metallic finishes allow floors to match both residential and commercial aesthetics. Flake systems remain popular because they hide imperfections and improve traction while adding visual depth.

Metallic epoxy creates a flowing, reflective appearance that works well in showrooms and high-end residential spaces. For areas that prioritize safety, slip-resistant additives provide grip without making the surface difficult to clean.

Gloss levels also vary. High-gloss finishes reflect light and brighten spaces, while satin finishes reduce glare. Because epoxy floor coating services customize each system, design choices stay flexible without sacrificing durability.

Long-Term Care and Performance Expectations

Epoxy floors stay low maintenance, yet they still benefit from routine care. Regular sweeping removes abrasive debris, while occasional mopping with mild cleaners preserves the finish. Because epoxy resists staining, spills clean up quickly without penetrating the surface.

Heavy impacts and sharp objects should still be handled with care. While epoxy holds up well, extreme abuse can damage the coating over time. When wear eventually appears, professionals can recoat or refresh the surface without removing the entire system.

With proper installation and maintenance, epoxy floor coatings often last many years in residential spaces and perform reliably in demanding commercial environments. The quality of preparation and materials determines longevity more than anything else.

Investing in the Right Epoxy Floor Coating Services

Epoxy flooring stays low maintenance, yet it still benefits from proper care. Routine sweeping removes grit that can dull the surface. Occasional mopping with mild cleaners keeps the finish bright and clean. Because epoxy resists stains, spills wipe up easily without penetrating the surface.

Heavy impacts and sharp objects should still be handled with care. While epoxy withstands significant wear, extreme abuse can damage the coating over time. Fortunately, professional contractors can repair or refresh epoxy systems without replacing the entire floor.

Well-installed epoxy floors often last ten years or longer, depending on use. Commercial spaces may require recoating sooner due to higher traffic, while residential garages often see extended performance. Quality installation remains the single most important factor in longevity.

Choosing the Right Epoxy Floor Contractor for Your Project

Epoxy floor coatings deliver strength, protection, and a clean, finished look when installed correctly. Custom Masonry provides professional epoxy floor coating services that protect concrete surfaces while improving both appearance and performance. From residential garages and basements to workshops and commercial spaces, our team applies epoxy systems designed to handle daily use, moisture exposure, and long-term wear.

Because proper preparation matters, Custom Masonry focuses on surface evaluation, grinding, and controlled application to ensure each coating bonds correctly and cures as intended. When preparation, application, and finish work come together, epoxy floors do more than look good. They stay durable, clean easily, and continue performing year after year under real-world conditions.

Leave A Comment